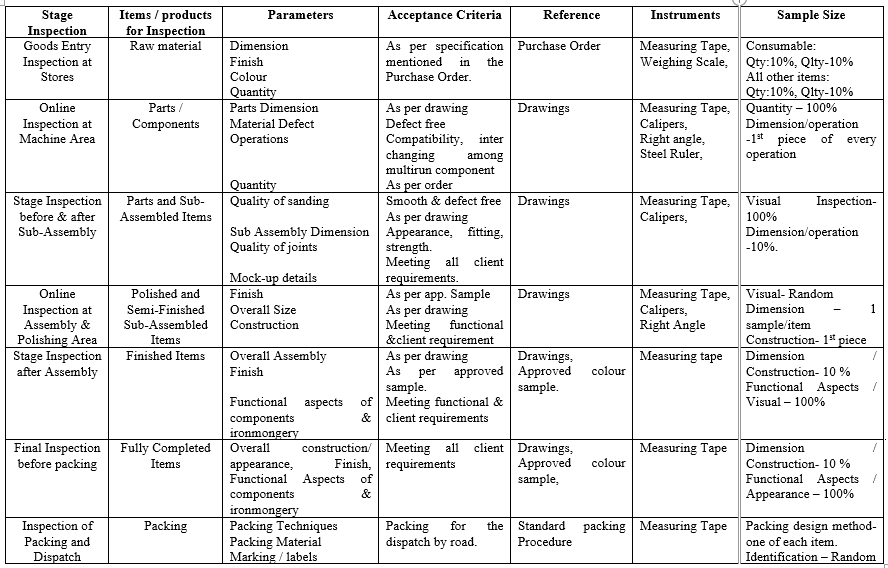

QUALITY ASSURANCE FLOW CHART

01. GOODS ENTRY INSPECTION AT STORES

02. ONLINE INSPECTION AT MACHINE AREA

03. STAGE INSPECTION AFTER SUB-ASSEMBLY

04. ONLINE INSPECTION AT ASSEMBLY AREA

05. STAGE INSPECTION AFTER ASSEMBLY

06. FINAL INSPECTION BEFORE PACKING

07. INSPECTION OF PACKING & DESPATCH

Goods Entry Inspection Procedure:

All in-coming goods received will be recorded in the Entry Book. The goods are then inspected. Items like mirror and marbles which sometimes goes directly to the project site are not noted.

The person responsible will be the Store Keeper.

Online Inspection at Machine Area:

All the raw materials will be checked for defects, finish & quality before the machining operations are started.

The first piece after every operation will be checked for its specifications.

The component will be checked for its compatibility and inter-changing ability with its mating component after all the operations have been completed. The quantity of the items will also be checked.

The person responsible will be the Quality Control Inspector and Supervisors

Stage Inspection after Sub-Assembly:

One sample of each and every item will be Dry Assembled and Quality Control check will be done as per specification as per the given drawings.

All components received from the Sub-Assembly will be checked for the quantity and is noted. Components are inspected on the percentage basis for its dimension and the accuracy of operations done on it with respect to the specifications given.

Visual Inspection will be done on all the components checking for defects like bad veneer joints, veneer damage, material with knots, twists etc. & improper sanding operation.

The person responsible will be the Quality Control Inspector and Supervisors

Online Inspection at Assembly Section:

The proper usage of joinery accessories like glue, screws, dowels & hinges while assembling the unit, will be checked.

One sample of each component is measured for dimension as per specifications.

Random inspection of components for the colour finish as per specification.

Sample of the ironmongery will be inspected for its specifications as per the approved sample.

First piece inspection of the completely assembled item will be done to check the construction details with respect to the specification given in the Assembly drawing.

The person responsible will be the Quality Control Inspector and Supervisors

Stage Inspection after Assembly:

All the finished items received from the Assembly will be inspected, for the following aspects:

Good finish, correct colour stain as per the approved sample, smooth functional aspects of drawers & doors, correct ironmongery usage as per the approved sample, the construction details of the whole unit and free from any kind of defects.

The person responsible will be the Quality Control Inspector and Supervisors

Final Inspection before Packing:

All the finished items received from Assembly after the final touch-up will be inspected for the following aspects:

Good finish, Correct colour stain as per the approved sample, smooth functioning aspects of the drawers & doors, correct ironmongery usage as per the approved sample, construction detail of the whole unit, identify left hand & right hand units and free from any kind of defects.

The person responsible will be the Quality Control Inspector and Supervisors

Inspection of Packing and Despatch:

The quantity, quality and the dimension of the packing material which is to be used, will be checked.

Packing will be checked, so that the furniture reaches the client or site, without any damage.

Proper packing procedures will be followed.

The items will also be marked and labeled.

The Items will be checked if they are stacked properly in the Trucks / Tempos.

The person responsible will be the Quality Control Inspector and Supervisors

Mock Up Items Inspection Procedure:

All Mock-up Items will follow the same procedure as the regular items while in production. Inspection will be done at all stages.

The first stage inspection is done after the whole item is dry assembled at the Sub-assembly section. All aspects like dimension, design, ironmengery filment, aesthetic look, construction details and finish are checked. The items will be checked and inspected before it is been sent for polishing.

At the second stage all items are inspected after it is been completely assembled after the final polishing is done. Colour finish as per the approved sample, functional aspects of the unit, correct ironmongery usage and the construction details will be checked. The items will then be sent for packing after the necessary rework is carried out if any.

At the third stage the items will then be packed in special boxes made as per specification taking into consideration the way it is being freighted. Packing inspection will be made to ensure that the boxes can sustain the journey, without damaging the items inside it.

PLANT AND MACHINERY

List is as follows:

Portable for site:

Cutter Machines = 6

Planner Machines = 5

Thickness / Size Planner = 4

Router Machines = 3

Drill Machines = 35

Air Compressors = 5

Sanding Machines = 40

Hand Cutters = 20

Jigsaw Machine = 2

Cordless Drill Machine = 12

Cordless Pneumatic Nailer = 12

Cordless Cutter Machine = 15

Miter Saw 10” = 2

At Workshop:

Cold Press = 1

CNC Router = 1

Panel Saw = 2

Planner Machines = 2

Edge Binder Manual = 1

Edge Binder Automatic = 1

Spindle Moulder Machine = 1

Router Machines = 3

Drill Machines = 12

Jigsaw Machine = 2

Air Compressors 15kg = 1

Sanding Machines = 15

Hand Cutters = 4

Domino Machine = 1

Paint Booth 18’ x 12’ = 1

Electric Dryer 18’ x 12’ = 1

Miter Saw 10” = 2

Pneumatic Nailer = 6